Consider the alternative

The increasing costs of lead theft are leading building owners, estate managers and specifiers to consider viable alternatives. Zinc is one of the most likely choices, but can you be sure you choosing a green alternative? Jonathan Lowy, Product Manager at VMZINC, states that the answer is a resounding ‘Yes’.

The increasing costs of lead theft are leading building owners, estate managers and specifiers to consider viable alternatives. Zinc is one of the most likely choices, but can you be sure you choosing a green alternative? Jonathan Lowy, Product Manager at VMZINC, states that the answer is a resounding ‘Yes’.

Zinc is among the most sustainable metals used in construction today and has been used on the roofs of Paris for almost 200 years. VMZINC rolled zinc products are used in construction industries throughout the world for their sustainability, distinctive appearance and low maintenance requirements.

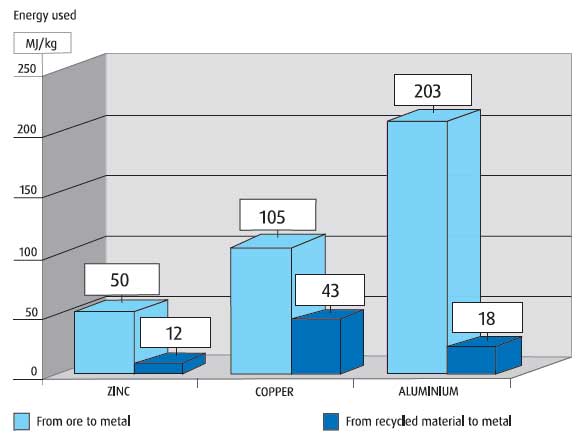

As with VMZINC façade and rainwater systems, manufacturing processes for our standing seam system present a low environmental impact, particularly with regard to energy expenditure. As the comparative energy expenditure diagram shows, less energy is required to extract zinc from the ground than the other principal metals, and the figures are even more favourable for recycled zinc.

Such minimal use of energy in the production of zinc clearly indicates its contribution to sustainable development. 95% of old rolled zinc recovered every year in Western Europe, currently estimated at 100,000 tonnes, is reused. This represents savings in mining resources of between 1 and 2 million tonnes.

The VMZINC standing seam system benefits from zinc’s self-protecting patina which develops as a result of exposure to water and carbon dioxide. Over the last 50 years the quantity of sulphur dioxide in the atmosphere has been greatly reduced. SO2 being the key agent of corrosion means that corrosion rates are now 1μm per year. With an initial thickness of 0.7mm, the estimated life span of rolled zinc is over a hundred years. VMZINC undertakes Life Cycle Analysis (LCA) tests on its products and publishes Environmental Product Declarations (EPDs), such as BRE Environmental Profiles, available from our website www.vmzinc.co.uk and www.greenbooklive.com.

The VMZINC standing seam system benefits from zinc’s self-protecting patina which develops as a result of exposure to water and carbon dioxide. Over the last 50 years the quantity of sulphur dioxide in the atmosphere has been greatly reduced. SO2 being the key agent of corrosion means that corrosion rates are now 1μm per year. With an initial thickness of 0.7mm, the estimated life span of rolled zinc is over a hundred years. VMZINC undertakes Life Cycle Analysis (LCA) tests on its products and publishes Environmental Product Declarations (EPDs), such as BRE Environmental Profiles, available from our website www.vmzinc.co.uk and www.greenbooklive.com.

These provide users with comprehensive, reliable and transparent information on relevant environmental characteristics. The information is also used by VMZINC as the basis for its eco-design approach. A wide range of zinc roofing and cladding systems have been audited with the systems receiving a Green Guide rating of up to A+. These profiles can then be applied to the BREEAM (BRE Environmental Assessment Method) allowing VMZINC to contribute to schemes such as the Code for Sustainable Homes.

The VMZINC standing seam system is also highly cost-effective, both from an initial procurement and design life perspective. Whether for new build or refurbishment, the VMZINC standing seam system has been designed to complement a wide range of building materials and styles. The finishes available offer exceptional colour stability. This ensures that maintenance requirements will be minimal throughout the system’s design life and that the material’s installed appearance will be retained for many years.

VMZINC’s versatile standing seam system can be used for warm or cold roof constructions. VMZINC ornaments also benefit from the above mentioned benefits.

A few years ago a grade II listed bandstand on Clapham Common, originally erected in 1890, was completely refurbished using VMZINC. Among factors affecting zinc’s specification by architects Dannatt Johnson were its resistance to corrosion, low weight and VMZINC’s ability to meet the complex roof design requirements.

For more information visit www.vmzinc.co.uk