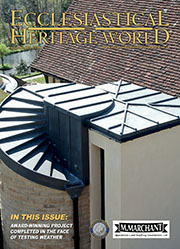

Brand new ‘Grade One-listed’ building is in line for Roofing Award

The project to install the roofs onto seven new houses at Stanmer House in Brighton was an unusual one, to say the least. The houses are built on the existing foundations of the old kitchen block at the 18th-century Palladian-style mansion, which was demolished when the repairs were deemed impracticable.

The project to install the roofs onto seven new houses at Stanmer House in Brighton was an unusual one, to say the least. The houses are built on the existing foundations of the old kitchen block at the 18th-century Palladian-style mansion, which was demolished when the repairs were deemed impracticable.

However, the building materials and the style of the new build has to match the previous building as they form part of the Grade One-listed property, together with the main house, which was built in 1723-4.

The existing slates were carefully measured where the new ones were to join those already existing, so the correct sizes could be ordered. The contractor, Richard Soan Roofing Services, had delivered 46 tons of 20 x 12-inch Westmoreland slate and two tons of 26 x 22-inch; on completion of the project there was less than half-a-ton of surplus slates.

Between the rafters Celotex insulation was fitted, leaving a 50mm air gap, and Klober air breather membrane was laid over the entire roof slopes, including the vertical cheeks, and temporarily secured with battens.

The slates were removed from pallets, sorted into various lengths and individually holed. The coverage of each size of slate was carefully worked out and the batten gauges calculated to make the best possible use of the available slates. The slates were very carefully selected and laid to a random pattern, secured with 38, 45 and 50mm copper clout nails depending on the size of the slate.

The verges were bedded in cement mortar containing sharp sand on a Westmoreland slate undercloak. The slating was neatly cut at valleys and hips.

Leadwork

On the run-out gutter, Code 6 lead was laid on a Class A Moiststop underlay paper, which was in turn laid on top of the ply deck with timber rolls. On the sloping valleys a layer of Class A Moiststop paper was laid on timber lay boards and Code 5 lead dressed over the timber fillets.

Lead hips and ridge were fitted – along with timber rolls – including Code 6 lead straps at 300 mm centres. At abutments, Code 3 lead soakers and Code 4 lead cover flashings were also fitted.

The project has earned for Richard Soan Roofing Services the nomination as a finalist in the Roof slating category of the 2013 Roofing Awards.

A spokesman for the company commented: “As with most projects these days, we were provided with a very tight programme of works for this contract; but we are pleased to say we met our client’s requirements, even though at the start of the project we endured 10-days of lying snow.

“This project enabled us to train several improvers and other skilled operatives in the laying of Westmoreland random slate roofing, which means in the future we will be able to undertake more of this type of work on a larger scale, if required.

“Colin Kemp, who was our site manager for this project, is a Heritage Craft Roofer and he was able to pass on his expertise to all those working for us on the site. Colin’s attention to detail and the fact that he insists on everything being 100% is a great testament to him; this is clearly displayed in the craftsmanship achieved on this project, which quite simply is outstanding.”

The company are looking to repeat the success it had last year with the project at nearby Folkington Manor, when it scooped the award in the same category. That is in addition to Gold Awards for Health and Safety 2012 from the NFRC in 2012, 2011 and 2010.

For more information please visit www.richardsoan.co.uk