Authentic natural materials are less harmful to the environment...

In every field, materials are chosen according to requirement – managers, designers, specifiers and tradesman never just blindly ignore the properties of those materials in their selection – except it seems, in the building industry. We have been suggesting for many years that traditional building materials are, by their nature, ecological.

In every field, materials are chosen according to requirement – managers, designers, specifiers and tradesman never just blindly ignore the properties of those materials in their selection – except it seems, in the building industry. We have been suggesting for many years that traditional building materials are, by their nature, ecological.

Therefore, if new buildings used more traditional materials, the future values to the global environment would simply by its nature, become sustainable. At Traditional Technologies, over many years, we have researched and developed how to apply those authentic natural materials in a manner that suits both new and old buildings. We are able to competitively render new build projects with guaranteed traditional material that meet the essential sustainability demands of today.

The manufacture of natural limes and aggregates consumes less energy and produces less greenhouse gases than that of cement. The total energy content per tonne of lime-based mortar has the potential to be between 75 and 90 % of that for cement-based mortars. Bricks and blocks contain the majority of the embodied energy in a unit of wall. Cement based mortars have higher bond strengths than lime-based mortars and masonry laid using cement-based mortars cannot readily be separated, cleaned and reused at the end of its life. By contrast, Masonry laid using lime-based mortar has lower bond strength, so the mortar can be cleaned off the bricks easily, allowing them to be reused and simultaneously allow normal thermal expansion/contraction with a building substrate.

Natural materials have extraordinary attributes for our future...

Walls designed and built with lime-based mortars have more tolerance to movement caused by thermal and moisture action. Movement within masonry walls built with lime-based mortars can be accommodated in the individual bed joints between the masonry units, and therefore reduces the need for vertical movement joints. Walls also gain improved ‘breathability’ to water and water vapour, which reduces the likelihood of frost failure of the unit materials and improves the internal environment. Lime-based mortars are capable of self-healing microscopic cracks by ‘plastic’ flow and diffusion. With Traditional Technologies applications they also have unique and long-lasting active qualities that literally continue to suck the moisture out of the wall. Just breathable is not good enough. We need to actively remove ingress moisture and use a poultice. We actually only want water to go one way.

Conservation and repair is the area of construction with the longest modern history of use, as it includes the preservation and restoration of historic buildings. Importantly, Traditional Technologies establishes the composition of the original mortar – both the binder and the aggregate – and we attempt to sympathetically match the new mortar to the original, provided that there is no evidence that the original mortar has been detrimental to the masonry.

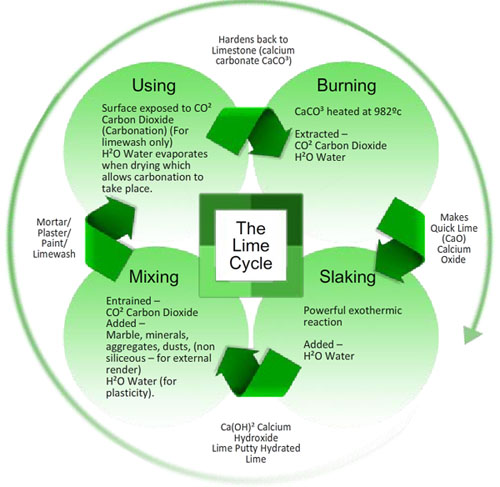

Binders from limestone are produced by kilning and utilising high-energy inputs. Significant efforts are continually being made by binder producers to reduce their energy consumption and more recently, their carbon dioxide emissions; by switching from hydrocarbons to other fuels and by improving their production processes.

Exposure of lime-based mortars to the atmosphere over prolonged periods absorbs most, or all, of the carbon dioxide that was driven off during their high temperature manufacturing process – known as carbonation. i.e. recarbonate; by contrast, cement-based mortars do not normally fully re-carbonate. Some calcium limes (CLs) are now being produced using alternative fuels, including biomass, and this process has the potential to deliver near carbon-neutral lime-based mortars.

• For further information visit http://www.limeworks.net/