Building Limes BS/EN459, revised Standard to be introduced.

The revision of EN 459 (BS/EN459) Standard for Building Limes has been a protracted process that started in 2004. The final draft is now at the stage of being approved at National level within the EU Nations. The revised Standard re-classifies Building Limes as follows:3.4 Lime with hydraulic properties

Building lime consisting mainly of calcium hydroxide (CL), calcium silicates and calcium aluminates. It has the property of setting and hardening when mixed with water and/or under water. Reaction with atmospheric carbon dioxide is part of the hardening process. Lime with hydraulic properties is divided into three subfamilies, natural hydraulic lime (NHL), formulated lime (FL) and hydraulic lime (HL).

5.2.1 Natural hydraulic lime (NHL)

Natural hydraulic lime is a lime with hydraulic properties produced by burning of more or less argillaceous or siliceous limestones (incl. chalk) with reduction to powder by slaking with or without grinding. It has the

property of setting and hardening when mixed with water and by reaction with carbon dioxide from the air (carbonation).

The hydraulic properties exclusively result from special chemical composition of the natural raw material.

Grinding agents up to 0,1 % are allowed. Natural hydraulic lime does not contain any other additions.

5.2.2 Formulated lime (FL)

Formulated lime is a lime with hydraulic properties mainly consisting of air lime (CL) and/or natural hydraulic lime (NHL) with added hydraulic and/or pozzolanic material. It has the property of setting and hardening when

mixed with water and by reaction with carbon dioxide from the air (carbonation).

5.2.3 Hydraulic lime (HL)

Hydraulic lime is a binder consisting of lime and other materials such as cement, blast furnace slag, fly ash, limestone filler and other suitable materials. It has the property of setting and hardening under water. Atmospheric carbon dioxide contributes to the hardening process.

The question is whether it is safe to use FLs and HLs in Restoration and Conservation. The European Committee recogniced the need to have a declaration of constituents in the binders to protect the User. After lengthy discussions it was agreed that FLs will have to contain a constituents declaration as follows:

Declaration of composition for formulated lime

D.1 Main constituents content to be declared by the producer

D.1.1 Building lime according to EN 459-1: CL and NHL.

D.1.2 Cements according to EN 197-1 (CEM I, CEM II; CEM III) exclusively on the basis of the constituents

in D.1.3. Cement contents are identified according to their normative designation of kind of cement.

D.1.3 Other constituents

D.1.3.1 Portland cement clinker (see EN 197-1) written (K).

D.1.3.2 Natural pozzolana (see EN 197-1) written (P).

D.1.3.3 Natural calcined pozzolana (see EN 197-1) written (Q).

D.1.3.4 Limestone (see EN 197-1) written (L, LL).

D.1.3.5 Granulated blastfurnace slag (see EN 197-1) written (S).

D.2 Minor constituents

Individual minor constituents, allowed up to 5 % in mass without declaration by the producer, if total minor

component additions exceed 10 %, all minor constituents shall be declared.

D.2.1 Components listed in D.1.3.

D.2.2 Calcium sulfate (see EN 197-1) written (G), see Table 20 – chemical requirement for formulated lime.

D.2.3 Silica fumes (see EN 197-1) written (D).

D.3 Additives

D.3.1 Organic additives must be declared under the formulated lime name on CE mark when the content

exceeds 0,2 % in mass. The actual amount and types shall be declared.

D.3.2 Mineral additives, like compounds of iron or tin for treatment of chromium are declared if they exceed

1 % in mass.

D.4 Declaration of composition

The constituents of formulated lime are limited to the constituents listed in D.1, D.2 and D.3

In the declaration of the composition of formulated lime, all constituents above 5 % by mass should be declared.

The compliance with the revised Standard is indicated on the products bags by the

This contains amongst others the number of the Certificate of Conformity and information on relevant essential characteristics (such as “Contains cement etc…)

What to look for: A “CE” Mark on bags of NHLs, FLs and HLs is the assurance that the products comply with the Standard.

Almost invariably FLs and HLs will contain cement and although the mechanical performance characteristics can be similar to NHLs or better (after all by “formulating” one can improve the basic performance of any product), these products are TOTALLY unsuitable in the Conservation and Restoration sector.

Suppliers of materials not bearing the “CE” Mark are not subject to the Standard but there are instances where the Standard’s denominations are used although there is no compliance or no CE Mark on the bags... This cannot be acceptable.

Binders and related mortars used in Conservation and Restoration should be suitable and compatible with the structures in which they are used. Suitability and compatibility should not only be measured by mechanical performance but also by the chemical composition of the products.

Mechanical performance (Elasticity moduli, capillarity, breathability, water retention etc….) can easily be improved or modified by using additives. Indeed there are cases where we do recommend the use of some additives, especially natural derivatives such as water retainers (Methylcellulose) or water proofers (Magnesium Stearate). Workability and frost resistance can be improved with air entrainers. If these are used in conjunction with Natural products such as NHLs they will enhance the NHLs performance without altering their purity.

The chemical composition of cement or some pozzolans and other hydraulic materials such as GGBS (Ground Granulated Blastfurnace Slag) and PFA (Pulverised Fly Ash) is however so remote from the building materials of the past and so incompatible that advocating their use in ancient buildings is equivalent to sabotaging them.

Cement constituents such as high levels of Aluminates, are increased even further by the addition of GGBS. High level of Aluminates are associated with sulphate attack. Cement also contains Chromium VI (allergic compound to the skin). This is indicated by the risk phrase R43 in the COSH declaration. The presence of this phrase (R43) denotes the presence of cement.

Our opinion is that products such as FLs and HLs are the result of wanting to give hydraulic properties to Hydrated Limes (CLs), available cheaply and in abundance, devised by producers that cannot offer NHLs.

Whatever the reason for producing FLs and HLs is, no attempt should be made to encourage their use in the Conservation and Restoration sector offering arguments related only to performance. It is not an honest approach.

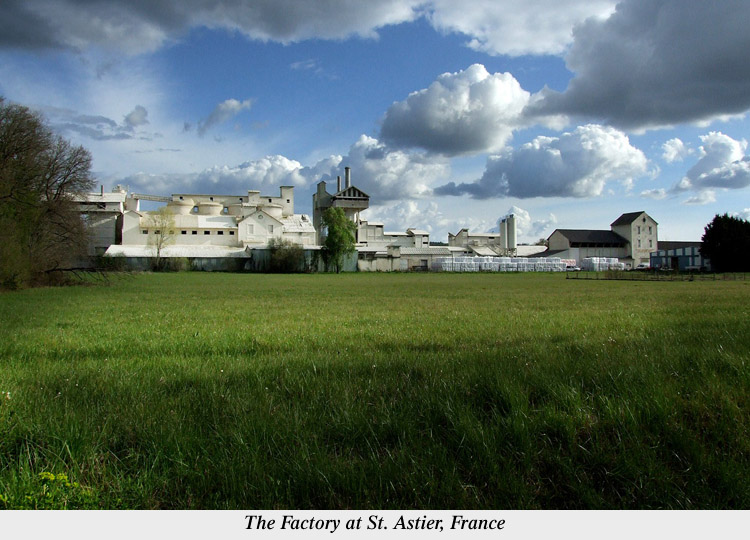

St. Astier Limes have an “open book” policy of transparency. The St. Astier NHLs are supported by complete data on Mineralogy, Chemical composition and Tests on the related mortars performance over 24 months have been published since the year 2000.

Contrary to the “trend” of testing mortars at Relative Humidity (RH) of 60%, these tests are conducted in accordance with the BS/EN 459 Standards at 90%RH. This is much more representative of the average RH conditions in the UK and Ireland. It is dangerous to test at 60%RH because this promotes setting patterns NOT possible to be obtained in an ambient with higher RH, such as the RH prevailing in UK/Ireland.

What to look for: check that the curing of mortars before testing has been conducted at a realistic RH. Lime mortars should be tested in accordance with the BS EN459.1 and 459.2 Standards.

This will avoid adopting mortars that achieve the required compressive strength at 60%RH but will not perform at 90%RH. Attempts are been made at the moment to change the testing methods in UK to 60%RH in order to suit products that would not otherwise perform. This can (and has) produced failures that should not have happened if the products were tested in accordance with BS/EN 459 in the first place.

The St. Astier Technical Department This email address is being protected from spambots. You need JavaScript enabled to view it. is freely available to anyone wishing to discuss this article or any other subject related to building limes and their application. www.stastier.co.uk