Lime mortars give protection to Kent and Caen stone

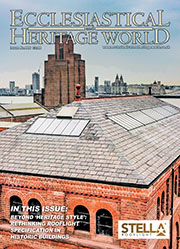

Parapet frieze prior to and following conservation

All Saints’ Church in Laxfield is a classic Suffolk wool church, with a long, wide nave and a superb west tower dating from the mid 15th century. The tower is 100ft high and originally built of Caen stone dressings with fine flushwork flint panels – as you’d expect to see in East Anglia – and much more unusually with large expanses of Kentish ragstone ashlar.

There have been long-standing problems with stone decay, as evidenced by 19th and 20th century restorations. Those had seen a large part of the very finely carved Caen parapet frieze replaced with rather lifeless carving in Clipsham – making the medieval work that remained of great significance, despite its very poor condition.

Much of it had been laid off-bed and was delaminating, while other areas were crumbling behind old and very hard cement mortar repairs. Cement mortars had been used widely throughout the tower and in places was starting to come off in sheets – both from the Caen and from the Kentish rag – such that it had been necessary to cordon off the base of the structure for safety reasons.

Skillington Workshop Ltd, specialist stone and plaster conservators based at Grantham in Lincolnshire and working throughout the UK, were brought in by the church’s architect Ruth Blackman in 2008, to survey the tower from a cherry-picker. A specification was drawn up which put the emphasis on preservation of the historic fabric, achieved by lime mortar repairs with only an absolute minimum of stone conservation.

In the case of the Kentish rag, which was laid in large ashlar blocks, a choice of replacement stone was in itself problematic. The work, which attracted funding from English Heritage, went out to competitive tender in two phases – covering the south and west faces in 2009 and the north and east in 2015. Skillingtons won both phases of work, with phase one costing around £150,000 and phase two about £125,000 – both with added VAT.

A typical area of walling after conservation

Much the same team of conservators worked on both phases, including Skillingtons’ team based in Cambridge. The works were project managed by Dr David Carrington ACR, who is the company’s managing director and has some 30 years experience in stone and building conservation.

Achieving good mortar repairs was of critical importance to the project’s success. Great care was taken to get a good match to the different stone types and to the pointing. A palette of mortar colours was needed for the Kentish rag in particular. Mortars were based on either chalk lime putty or the now no-longer-available Singleton Birch NHL2 hydraulic lime. Where repairs were deep they were built up in layers and reinforced by armatures.

In the event no replacements were needed for the ragstone; but to achieve that some large-scale mortar repairs were needed to stringcourses, utilising tile and slate reinforcement. The more decorative Caen stonework, such as the parapet frieze, was given a lime sheltercoat, carefully matched to the colour of the stone. That not only gave further protection, but also provided visual unity where there were old Clipsham stone replacements.

A number of replacements were needed for the Caen stone, in carefully selected new Caen – mainly to decayed copings and weatherings, where it was felt that not only would mortars not survive well but the architectural function of the stone was of critical importance to ensure the survival of adjacent elements.

A great advantage of carrying out the work in two phases was the opportunity to review the success of the first phase from close up on the scaffolding some six years after it was first done. All the repairs were still in excellent order, which instilled great confidence in implementing the second phase in the same way.

The completed project has left the tower in good order for many years to come and has won many plaudits – not least for the success achieved using lime mortars – and it was shortlisted for the 2016 SPAB John Betjeman awards.

For more from this company visit their website www.skillingtons.co.uk