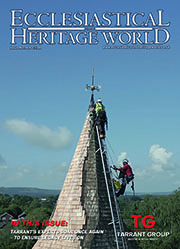

Heritage Roofing

Heritage roofing - maintaining our iconic buildings

The UK is home to some of the most iconic buildings in the world, from stunning churches and cathedrals to historic stately homes. Each and every one of these remarkable feats of architecture requires regular maintenance to ensure they remain in the very best condition, allowing them to be enjoyed for generations.

Lightning Protection

When lightning strikes are you protected against this act of God?

The issue of lightning protection in churches is one that has exercised this publication for many years. In this four-part series of spotlights on the issue we will be revisiting various aspects of the subject, beginning with an overview of current thinking.

Traditional Lime

Lime: it’s better for buildings – and for the environment

It is now fairly well known that cement is not good for old buildings and that lime mortar should be used. But why? What are the advantages and what are the disadvantages? In order to begin to answer those questions it is necessary to understand the nature of traditional building, the process by which buildings used to be built, and how it differs from modern construction, the process by which we build today.

Audio Visual

Audio visual equipment in church buildings

This guidance is issued by the Church Buildings Council under section 55(1)(d) of the Dioceses, Mission and Pastoral Measure 2007. As it is statutory guidance, it must be considered with great care. The standards of good practice set out in the guidance should not be departed from unless the departure is justified by reasons that are spelled out clearly, logically and convincingly.

Read More...

CRE Events

Churches are coming under starter’s orders for CRE 25

Churches across the nation are beginning to make preparations for their visit to Christian Resources Exhibition’s CRE 25.

Insurance

You need to ensure that reasonable precautions are in place at your church to keep it safe for those who use it. To do this, you need to think about what might cause harm to people.

You will then need to decide if the precautions already in place are adequate. If they are not, you may need to identify further action to prevent any danger. When done formally, this is known as a risk assessment.

LPOW Grants

£23 million government package to support restoration of thousands of listed places of worship

Heritage Minister Sir Chris Bryant has announced that the Listed Places of Worship Grant Scheme will be extended into the next financial year, providing £23 million so that thousands of historical buildings, including churches, synagogues, mosques and temples, can carry out restoration work.

Lead Roofing

Lead is one of the oldest materials in the roofing industry and is still commonly used throughout the world today.

Lead roofing is a traditional roofing method which has been used in the industry for hundreds of years, and is therefore proven to be extremely reliable. Lead roofing, and sand-cast lead, in particular is ideal for old buildings such as churches or historical renovations, whereas milled lead roofing is a mass-produced alternative, used for precision and accuracy in homes and commercial buildings alike.

Home

RESTORATION AND CONSERVATION MORTARS

Today all of us are charged with the responsibility of ensuring the survival of our historical and vernacular built heritage through careful and considered conservation, restoration and renovation.

Today all of us are charged with the responsibility of ensuring the survival of our historical and vernacular built heritage through careful and considered conservation, restoration and renovation.

All too often buildings are repaired with inappropriate materials and poor skills. Many are the subject of interventions that in time lead to their total loss. Others are simply changed out of all recognition.

In most cases, the mortar used for repairs, restoration or conservation contains cement.

In these buildings, the use of cement mortars promote condensation build up, salt reactions and, generally, drastically affects the long term survival of the building.

St. Astier natural hydraulic Lime mortars provide a valid alternative to cement mortars or cement/lime mixes and, if applied properly, they will have a much longer life. Environmentally they offer far greater efficiency than cementicious mortars by re-absorbing CO2 and not compromising the recyclability of the building materials.

I will now go through the main characteristics that we look for to qualify a mortar as SUITABLE. These are our RULES (or the 10 Commandments....)

- COMPATIBILITY

- LOW CAPILLARITY AND SHRINKAGE

- ADEQUATE Ca(OH)2 OR FREE LIME CONTENT

- RESISTANCE TO FROST

- RESISTANCE TO SALTS

- VAPOUR PERMEABILITY (BREATHABILITY) & GOOD SANDS

- EARLY SETTING, GOOD ELASTICITY/WORKABILITY/RE-WORK ABILITY

- SUITABLE COMPRESSIVE AND BONDING STRENGTH

- ENVIRONMENTAL CONSIDERATIONS

- CORRECT WORKING AND SITE PRACTICE

A brief look to each of these points.

Rule 1: COMPATIBILITY

We prefer to look at compatible mortars rather than LIKE FOR LIKE. The reason for this is that today in most cases, it is NOT possible to reproduce exactly the mortars of the past.

The binders are different, the sands might not be the same. In the EU a lot of sand pits have closed and some of the historic pits just do not exist anymore.

Compatibility should be both Chemical and Mechanical.

In chemical terms what is important is that mortars introduced into existing structures will NOT chemically react with existing mortars and the surrounding masonry by introducing in the masonry soluble salts such as Sulphate (Gypsum) or Aluminates causing Sulphate attack or Alkalis (Potassium and Sodium) causing a reaction with the sand (Alkali-Silica reaction).

In Mechanical terms, mortars should NOT be too dense to impede breathability or have poor Elasticity resulting in cracks that will allow water/moisture penetration.

Rule 2: Look for LOW Capillarity AND Shrinkage

These are both properties affecting the durability of the mortar.

High capillarity allows moisture penetration and, if a mortar has poor breathability (such as cementicious mortars), there will be creation of condensation and the problems associated with it.

The main causes of high capillarity are poor sands and void structure and high quantity of Free Lime in the binder. Free Lime crystallises in the voids, reducing their size and therefore increasing their capillary action.

Poor building details and drainage increases the amount of water in touch with the masonry which can be absorbed by capillary action.

High Shrinkage is also a source of cracking and it is to be avoided.

Shrinkage is caused by:

1. Inadequate suction control of the masonry units. If suction is not controlled by adequate wetting or dampening of the masonry, water in the mortar will be sucked into the masonry. The mortar is therefore deprived of the water necessary for its hydration with the result that the mortar becomes friable as its matrix has not formed properly.

2. High free lime content. This is because free lime is very fine and demands more water at the moment of mixing the mortar. The evaporation of this water leaves micro cracks in the mortar (Shrinkage)

3. Wrong dosage in the mortar mix. Commonly occurring when too much binder is used. Over-binding produces a heave effect, causing cracks.

4. Poor mixing of the mortar can cause over-binding in certain areas and low binding in other with cracks as a result

5. Poor protection from drying wind, direct sun, driving rain and frost when the mortar is still fresh will also cause cracking and shrinkage. So will poor Curing: mortars, especially lime mortars, need time to cure. So, depending on the weather conditions, mortar need to be dampened for few days in warm weather or in the presence of drying wind.

In cold rainy weather and when frost is expected, fresh mortars have to be covered to prevent damage. This is normally done with hessian sheeting.

I briefly mentioned Low Free Lime content. I think this deserves a little more explanation:

Rule 3: Adequate Ca(OH)2 OR FREE LIME content

FREE LIME / HIGH CALCIUM LIME / AVAILABLE LIME / AIR LIME/ HYDRATED LIME / PORTLANDITE/ FAT LIME/SLAKED LIME

They are basically all the same and consist of Calcium Hydroxide - Ca(OH)2

ALL CALLED CL IN EN 459 (CL70/CL80 ETC..) where 70,80.90 is the % of Ca(OH)2 that they contain.

Free Lime makes mortars more workable and this is liked by the mason. However Free Lime affects a number of important properties in mortars such as:

1. Setting and hardening time: an early set and a relatively quick hardening are important to be able to build with some speed.

Initial setting of an hydraulic mortar is within 1 or 2 hours, the final set is within 24 hours. The final set determines the moment when the mortar cannot be re-worked.

Hardening takes longer. It is the time that the Calcium Silicates and other hydraulic components in a mortar take to become insoluble. In the European Norms both properties are taken into consideration and the definition of NHL 2, NHL 3.5 and NHL 5 is based on the hardened strength at 28 days expressed in Newton per mm2.

Free lime is NOT hydraulic and needs contact with Air to re-absorb CO2 and reconstitute itself to CaCO3 or LIMESTONE. This process called CARBONATION may take a very long time. Damp environment, rain, location of the mortar (exposure to air) contribute to slowing and in some cases even stopping Carbonation. The result is that the mortar does not harden.

Free Lime will dissolve in water at a ratio of 1 to 6 and this is the reason why LEACHING occurs. Leaching not only is an unwanted visual effect but also deprives the mortar of some of the Binder with the result that you have a different mortar in the structure from the one specified.

2. Free lime, because of its fineness, increase water demand in the mortar. One of the causes of shrinkage, as already discussed.

3. It also increases capillarity by crystallising in the voids, reducing breathability

4. The reduction of the voids size affects also the frost resistance, as we will shortly see.

High free lime mortars such as 1:1:6 and 1:2:9 mixes or hydrated (powder or putty) lime mortars might not be as suitable as they are supposed to be. Careful judgement has to be made in relation to their use. This also applies to lime mortars made with hydraulic lime with very high free lime content now being sold in the UK market.

Rule 4: Resistance to frost

The reduction in void size by free lime crystallisation or a poor void structure caused by poor sands and the slow carbonation of free lime, makes the mortar more susceptible to frost damage.

Frost starts always from the surface and goes inward. Frozen water particles in the surface voids push the water in the voids behind further in and so on. If there is a good void structure accommodating the water movement, this process will not generate a pressure and the mortar will resist frost.

The size of the voids is also important: ice has a volume of 8% greater than water so it will exercise pressure if the voids cannot contain more that the water they already contain. This is the case in saturated mortars where the water absorbed during rain before frost occurs is occupying all the voids.

Hardened mortars with a good void structure will resist frost.

St. Astier NHL Mortars have been successfully used in areas of extreme cold such as Canada, Alaska, Norway, Finland, Denmark and wet/cold areas as part of Ireland and UK.

The basic principle is to avoid saturation of the mortar when still fresh, so protection at this stage is of extreme importance.

RULE 5: Resistance to salts

The same mortar will also resist the outward migration of salts contained in the masonry.

A Macro void structure in the mortar will accommodate the pressure exercised by salts when moving or crystallising.

When structures contain salts it is almost impossible to control them if they become unstable.Their behaviour is linked to the Relative Humidity which is typical to each salt. A lower RH will cause crystallisation, a higher RH will cause the salt to go into a solution and migrate.

If the void space is sufficient, these phenomenons will not cause a damaging pressure.

If crystallisation occurs, they stay in the wall and if there is no space in the voids the pressure can be great enough to crack the mortar. If they go into solution, they will eventually come out and can be cleaned off the wall.

Lime is hygroscopic, it attracts water, by doing so a new lime mortar used for re-pointing or rendering might attract moisture contained in the structure and therefore change the RH of the wall in which the salts are contained, causing their movement. So a high free lime mortar will absorb salts. This is fine if we are using a lime mortar to diminish the salts content in the wall. Once the lime mortar is saturated with salts, it can be removed and the salts with it. It is not so good if we wish to keep the mortar. In this case a NHL mortar with less free lime and a good void structure will obtain the required result.

The same type of mortar will not suffer from salts ingress promoted by external agents such as is common in marine environments.

This is work done in the Year 2000 at Atlantic College in Wales. The re-pointing of the Harbour wall is still in perfect condition 10 years later. The Mortar is an NHL 5 with very coarse sharp sand.

Rule 6: Vapour permeability (Breathability) AND good sands

A breathable mortar is essential in the control of condensation. No damp, no rot, a much better living environment.

It also helps in consuming less energy in heating. If a room is damp, a lot of the heating will go in drying out the damp before heating the room....

Hardened mortars with good breathability will dry faster than dense mortar. Saturation of the mortar is well reduced and so is the risk of frost damage.

St. Astier NHL mortars if compared to cement/lime mortars have a breathability

better by 200% !

The two main factors in achieving good breathability are:

- a relatively low Free Lime content in the Binder to avoid too much crystallisation in the mortar voids and the use of well graded sands in the mortar.

-The choice of good well graded sand is of paramount importance in obtaining a breathable mortar.

RULE 7 : Good setting, elasticity, workability

Setting and Hardening determine the work rate. They are also related to the mortar dosage, the water addition and the weather conditions during execution of the work. Protection and curing methods are directly connected with Setting, Hardening and Curing mortars.

So it is important to have a good idea on the Setting and Hardening properties of mortars to be able to determine that it will be suitable for the work, what particular precautions to use and for how long.

Elasticity determines the amounts of movement that the mortar will take before cracking. It is also relevant in calculating the positioning of joints. A good Elasticity will help in accepting thermal movements.

Workability of a mortar is in many cases left to the mason that is executing the work and almost invariably this result in excessive water addition to obtain the “plasticity” that masons like.

This is wrong as too much (or too little) water can have serious effects on setting time, shrinkage, capillarity and so on.

Information on the correct water addition should be given to the mason and supervisors should check that the instructions are followed.

RULE 8 : Suitable compressive and bonding strength

I am leaving this point towards the end not because I deem it less important but because I wish to put it into perspective.

It is no good to look just at quick setting and hardening. A very hard mortar, especially when made with cement, is NOT the solution to all requirements.

Quick setting and strong hardening have become synonymous with “a good mortar” since the advent of cement but in Restoration and Conservation Setting and Hardening should be only part of the evaluation to be made on the most suitable mortar for the job.

Of course we need setting and hardening, especially in adverse climatic conditions and seasonal work. But this should NEVER be to the exclusion of all other considerations made up to now such as Compatibility, breathability, elasticity and so on.

In Restoration and Conservation St. Astier NHL mortars comply with all requirements.

They set and harden faster and stronger than Lime Putty or hydrated lime without the use of Pozzolans ( a “dear” word to many but essentially a poorly known subject, open to uncertain results) or cement.

A note on this: many producers state that their product contains “pozzolanic” additions. This is in most cases cement. Just ask the question about Re-Working the mortar within 24 hours. If the answer is NO, the mortar most likely has a cement content.

The compatibility and other properties of NHL mortars ensure that performance and durability are achieved without the use of cement. They represent a logical and natural choice in the restoration and preservation of our built heritage.

RULE 9: Consider the environment

Lime mortars re-absorb CO2. St, Astier NHL mortars will re-absorb between 38% and 49% of the CO2 emitted in production.

NHL mortar are also non toxic and once hardened, they will not increase the water Ph.

Cementicious mortars can contain Chromium VI directly related to skin allergies and, depending on the type of cement used, components like Pulverised Fly Ash (PFA), Granulated Ground Blast furnace Slag (GGBS) and others that contain a number of dangerous elements such as Heavy Metals and many other toxic elements.

NHL mortars will also be easily removed from masonry units, allowing them to be re-cycled.

The breathability of St. Astier NHL mortars eliminates condensation and contributes to a better living environment for individual with breathing difficulties (Asthma, for example)

RULE 10: Correct working and site practice

Good materials can become useless if the correct site practices are not followed.

Good workmanship and supervision are essential.

If mortars are not dosed or mixed properly, if they are not cured and protected correctly, if they are applied badly, if the application surfaces are not properly prepared, if suction is not controlled, if salt movements are not taken into consideration and so on, the result will be a failure.

Architects, Engineers – Specifiers in general – should work with the Contractor to ensure that he has the necessary comprehension and skills to apply the mortars and follow the necessary site practice.

Is is, however, the responsibility of the mortar manufacturer to give Architects, Engineers and Specifiers all the information they require for the evaluation of the mortar to be adopted.

St. Astier Limes not only provide this information but also, when required, the technical staff actively work with the Specifier giving technical advice to establish the most appropriate mortar for the proposed intervention.

For more information, clarification or for any query please contact: This email address is being protected from spambots. You need JavaScript enabled to view it.

Or This email address is being protected from spambots. You need JavaScript enabled to view it.

Ugo Spano

St. Astier Limes Liaison Office